In the last article I gave the plans and details for the construction of Farmer Generic's Hovel. Contained in that article were the most important points of miniature construction, and the basics upon which all future items will follow.

In passing I might say that to prove out the previous article I built a house directly from the plans provided and timed myself (the real reason for the experiment) to see how long it would take. Eliminating the significant waiting periods between operators to allow glue or paint to dry, it took only 1.6 hours to build Farmer Generic's hovel! With proper care and forethought one could set up an assembly line, cutting out enough parts for seven to ten houses, working on one part at a time and assembling each in turn. Then painting each in turn and so on. One could easily turn out seven or eight in a five hour period.

DETAILlNG

In the previous article I left you with a rather bland looking building. Now lets try to give it a little more life. We are dealing only with BASIC detail! In later articles we can explore more intricate details, but right now, unless you are already an accomplished modeler I recommend you keep it simple.

To make a pleasing looking building you will have to pay attention to the basic detail. This includes:

-

1. Trim and shutters for the windows, either open or

closed.

2. Some form of door and door frame, possibly steps or stoop.

3. Some form of believable roof.

TRIM AND SHUTTERS: To make these take 1/16" by 1/4" balsa wood and cut off as many sections as desired for open shutters, in most cases two per window. Glue the shutters open on each side of the window. If you desire the shutters to be stained, "scribe" lines across or lengthwise to represent the louvers. Do not press too deeply, just enough to leave an indention. If you are going to paint them with a color do not scribe, as the paint will fill in any lines.

For closed shutters, simply glue a piece of 1/2" by 3/4" by 1/16" balsa over the outside of a window. Underneath the window glue a strip of balsa 1/16" by 1/16", long enough to overlap the window, but not enough to overlap the shutters. Cut a piece of 1/4" by 1/16" as an eave over each window and glue it on.

DOORS: Glue a piece of balsa into the door opening from behind. Do not worry about the exact size, just so long as it covers the entire opening. Now glue a 1/16" by 1/16" balsa strip into each edge of the outside of the door. Then next to that, on the wall, glue another 1/8" by 1/16" strip all around. This will complete the door frame. A small square can be glued to the middle of the door for decoration.

Dutch doors can be made with the top half open or closed. To show one closed, simply glue a piece of 1/16" by 1/16" balsa across the center of the standard door described above.

THACHED ROOFS: First choose a poster paint color of suitable khaki, dun, or brown. I use Richart No. 91 brown- paint the roof. When the paint is dry take grass cuttings that have dried and arrange them more or less parallel in neat rows end to end. Smear glue over the entire roof and lay the grass down in clumps. Don't worry if the stuff sticks all over the place, or it does not lay right - that's no problem.

Once the glue has dried take a scissor and give the roof a "haircut" by skimming over it, snipping off the protruding ends and cutting it down close to the roof. If you desire you can leave it natural now or you can paint it again with the same, or a slightly lighter shade of paint. A lot of paint will be required in covering the very rough surface sufficiently. Make sure you let the stuff overhang the edge of the roof then cut it off, giving a ragged appearance like real thatch.

FINISHING TOUCHES

Use your imagination when building these structures. A little extra effort will go a long way. Take a walk around your own house and notice little details that are part of it. For example, almost every building shows signs of being altered in some way. In one model I made a simple frame on the back side from two pieces of scrap lumber which gave the appearance of the supports of a small shed or lean-to that once rested on that side. Another detail was a bricked up small window high on one wall. This was done simply by gluing in trim strips and painting the bricks in over the basic white. I painted the entire building white to resemble stucco, then painted in the red brick where the stucco flaked or was knocked off.

Simple yellow floral designs on the green shutters add to the look of a peasant cottage. A doorknob is made from a straight pin, the type with bulbous or rounded heads used by seamstresses or use normal straight pins dipped in a blob of epoxy. To get the bead to form stick the pin upside down into a wood brace or window sill. That way the epoxy will congeal in a ball and not run down the shaft of the pin.

BUILDING CITY DWELLINGS

Most city dwellings are multi-storied affairs. This adds a bit more complexity for games (and a bit more interesting modeling). Most city buildings are four to five stories high in central Europe, or at least they were before WWII. Now they are mostly three. Generally three stories is about the most you will want on your table top or buildings will soon tower over the landscape.

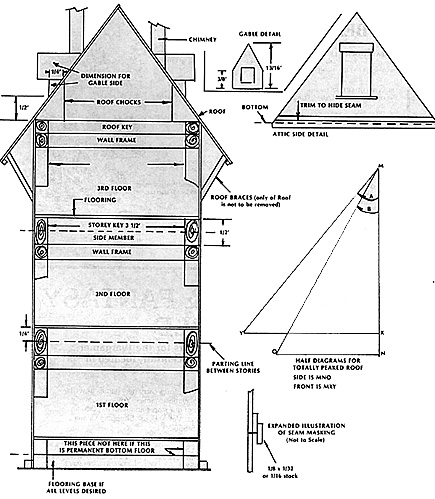

Shown in the plan is a three story house plus roof. You could of course add more stories by simply building higher, or make a two story building by dropping a story. Once again, all stories are modular and are keyed to fit into each other. The construction method for each story is identical to Farmer Generic's cottage EXCEPT that a floor is put into each story and a base key must be made to lock into the top of the floor below.

THE BASE KEY: Actually the base key is the same as a roof key except that it is permanently glued to the base of a story. The base key is composed of pieces of balsa 1/2" by 1/4" in dimension. To make a single key would take:

-

Two 1/2" by 1/4" pieces four inches long Two 1/2" by

1/4" pieces two and one half inches long.

Simply glue these together to make a frame 3" by 4" and glue into the bottom of a story, being careful to leave 1/4" showing below the bottom. This is the basic key and the protruding 1/4" will "nest" into the recess of the floor below just as the roof does in the building.

Before cementing the key frame into place (or building the story around it which works as well), glue a 3" by 4" piece of card over the side that will go inside the story (not the one that will protrude downward). This will form a floor to put stands of troops on. If you wish, put a structural strut down the long dimension of the floor underneath it and fasten it to the ends of the key to provide a firm base.

Note that the plan shows a three story building with one of the short sides removed to show the bracing diagram of keys and recesses. Remember that roof or story keys are never glued to the floor below them.

This basic structure (less trim, windows, and doors) requires balsa wood as follows:

-

10 pieces 1/4" x 1/4" by 4"

10 pieces 1/4" x 1/4" by 2"

12 1/4" x 1/4" by 1" (only for side cleats can be from scrap)

8 pieces 1/4" x 1/4" by 1/2" (for roof chocks, again need not be exact . . . can be scrap)

2 pieces 1/4" x 1/4" by 2" (for two chimneys)

8 pieces 1/4" x 1/4" by 4"

8 pieces 1/4" x 1/4" by 2 1/2"

Shown on the plan is a base into which the bottom story locks. By using this method all three stories can be made modular and interchangable. Otherwise make one story without a story key so it will sit flat on the table top. This flooring base should be made of thin strips of card. The easiest method is to lightly tack 1/4" strips of card to teh protruding key with pins. Then place the building as it is to sit on its base.

Now glue 1/8" strips cut to the width of the doors to resemble steps, or run 1/8" stock all around the base. LIGHTLY glue this stripping down so the glue does not ooze out from under the strip and glue the key to it and the base.

Also shown on the plan are templates for a totally peaked roof, that is one that slopes on all four sides to a common point. This type of roof is not common, bu a few such should be built for variety.

FINISHING: There will be a seam between each story which may be rather unsightly especially if they do not match exactly. This is quite commonplace so don't fret too much. To make a seam mask cut two strips (2 for each side) of small stock, either 1/32" or 1/16" by 1/8". Glue one strip down exactly at the bottom edge of the wall (NOT THE KEY) of that story. Glue the other strip over the first strip, offsetting it by one half its width as shown in the expanded illulstration. This will allow space to easily get the story on and off, and will mask the seam by having what seems to be trim around the base of the floor.

Gables are the hardest to make as they involve a lot of cut-fitting. One trick is to cut out the gable sides at the same time you cut out the attic side. This insures that they will both have the same angle from the vertical. Draw a series of parallel lines and place the bottom of the attic piece on the base line of one of these, draw a line of the pitch of the roof. Then, using a square and triangle draw vertical lines from each intersection of the parallel lines and the pitch line of the roof. The small triangle provided will be the exact gable size you need.

Back to Table of Contents -- Courier Vol. 2 #5

To Courier List of Issues

To MagWeb Master Magazine List

© Copyright 1981 by The Courier Publishing Company.

This article appears in MagWeb (Magazine Web) on the Internet World Wide Web.

Other military history articles and gaming articles are available at http://www.magweb.com