Something resembling armor was used in ancient days, but it was chiefly to strengthen the sides of the vessel to withstand the shock of the ram. Coming down to modern times, the Stevens family, who were such distinguished engineers, demonstrated that four inches of wrought iron plate would keep out spherical shot fired from the smooth-bore cannon of that day. Prior to 1812, explosive shells had been fired only from mortars, but Colonel Bomford of the United States army devised a long-chambered gun for firing shell directly at the target. This was called a columbiad.

Little progress was made in the development of the idea here, but General Paixhan, a celebrated artillerist of France, took up the idea and in 1822 perfected it. At the battle of Sinope nine Russian ships armed with smooth-bore shell guns opposed eleven Turkish ships armed with the ordinary cannon of the day. The battle lasted about an hour and only one Turkish ship escaped. French inventors were quick to realize the importance of this lesson, Napoleon III ordering the construction of his iron-plated floating batteries, used with such great effect at Kimburn about two years later; and the great French naval engineer, Depuy De Lome, designed armored frigates.

Wrought iron plates had defeated the common shell and the solid round shot, and now began a battle-royal between the gunner and the armorer. The spherical shot gave place to an elongated form with a sharp point. This penetrated the plate and the gun scored its first victory. The armorer, seeing he must defeat the projectile by breaking it up, welded a face of steel over the wrought-iron backing and evolved "compound armor." Then the "Palliser" shot was cast, the point "chilled," making it very hard, and this penetrated and broke up the steel face of the armor-plate. The armorer replied with a solid steel plate and the defeat of the gun was predicted, but it was not for long. A steel projectile was soon used and the gun scored another victory. Then came the nickel alloy, which rendered the armor tougher and less likely to break upon attack, but the gunner replied by adding chromium to the steel he used, and produced a projectile equal to the nickel armor.

Harveyized Armor

The American Harvey improved upon nickel steel by placing the armor-plate in the chamber of a furnace, covering the face with charcoal and heating the whole until the charcoal gave off some of its carbon, which was taken up by the face of the armor-plate. The plate was then " tempered," and Harveyized armor made a sensation in military circles.

William Corey, of Pittsburgh, Pa., in 1895, patented a method for compressing the plate after it had passed through all the former processes. According to his theory, super-carbonizing tends to crystallize steel. By his method the plate is reheated to a temperature of about 2,000 degrees and subjected to enormous pressure, which restores its former tenacity and actually reduces the cubic contents of the plate about 5%.

In response to these methods, the artillerist, by a unique device, added 15% to the efficiency of his projectile. He covered the hard tempered steel point with a cap of soft steel, increased its velocity, and achieved a wonderful result. A 6-inch shell passed through a 10-inch reforged Harveyized. plate, twelve inches of oak timbers, three boiler-plates of 7.16-inch wrought iron, and buried itself eight feet in the sand practically uninjured. A recent trial at the Indian Head proving grounds, Virginia, of a 6-inch plate made by the Carnegie company, according to German methods, showed a marked advance in the armor. At present Americans make better thin plate than found elsewhere, but the French and German methods have produced better heavy plate. The Bethlehem Iron Company and the Carnegie Company have secured rights to use European methods.

At present the gun has much the better of the argument, and its resources are not exhausted. A service charge in the United States navy produces a pressure within the gun of about fifteen tons per square inch. Wire-wound guns have sustained a pressure per square inch of thirty-two tons, and slow-burning powder has given a velocity of over 3,000 feet a second, and the gunner has these in reserve.

Velocity in Foot-seconds

This term means the number of feet a projectile flies in a second. The rate of speed at the muzzle of a gun is called muzzle velocity. " High-power guns" in the United States are those whose projectiles have a muzzle velocity of 2,000 or more feet a second. Sound travels 1,100 feet a second, and a bullet from the best modern rifles moves more than twice as fast.

The three chief reasons why a high velocity is desirable are:

- 1. When shooting at an object in motion, that the bullet

may shoot the mark before the object has time to move far.

2. Penetration and energy are greater with a high velocity, being approximately in proportion to the square of the velocity. A shot with a velocity of 2,000 feet a second would penetrate four times as far as a shot with a velocity of 1,000 feet a second.

3. The path of the projectile is not a straight line, but a curve, and at long range part of its course is so far from a straight line as to be above the target at which it is fired. Danger space is the horizontal distance through which the projectile passes when it is neither too far above nor too far below to strike the target. The higher the velocity the straighter the path of the ball. A shell thrown from a mortar at an angle of 55 degrees or 60 degrees has a danger space as wide as the deck of the vessel at which it is aimed; a shell from a "high power gun" aimed directly at the target has a much wider danger space.

Gun Making

The invention of gunpowder is popularly ascribed to two monks, Roger Bacon, who wrote of it in 1267 and Bertholdus Schwartz about 132o, but there is ample evidence to show that gunpowder or something very much like it was used by the Chinese in the propulsion of rockets 1,000 years before, and the exact formula for gunpowder was known to the Arab chemists as early as the close of the 8th century. The Moors early introduced fire-arms into western Europe and are said to have used artillery against Saragossa (A. D. i i 18) and it seems certain that a little later they defended Niebla by machinery which threw darts and stones by the means of fire. Artillery is said to have been used by Henry III of England against the Duke of Gloucester in 1267, by the Spaniards against Cordova in 128o and it is shown by the expense accounts of Edward III that cannon were used in his wars.

Until recently, nearly all guns were made from cast iron. Sir William Armstrong said that for his first experiments he was unable to obtain steel large enough to make a gun with calibre one inch in diameter. It was the need of some material stronger than iron for use in projectiles and guns that stimulated Bessemer in his effort to make cheap steel. His discovery revolutionized gun making.

A "Built-up" Gun

The principle parts of the gun are, the tube, a hollow steel forging extending the full length of the bore, the jacket, covering about two-fifths of the tube; the jackethoops shrunken over the jacket; and the chase-hoops shrunken over that part of the tube in front of the jacket.

The gun is subjected to two stresses, one transverse, the other longitudinal. The tube takes up the greater part of the transverse, and the jacket the longitudinal stress.

Let us suppose a half dozen hoops, placed one within another and fitting loosely. An expansive force exerted within the inner hoop will burst it before much stress is felt upon the next hoop and the stress being delivered from one to another successively, hardly more force is required to burst all the hoops than to burst any one. Suppose another arrangement of the hoops by which the first hoop is clasped by the second and the second clasped tighter by the third, and so on to the outer one. The expansive force then exerted within the innermost hoop must be sufficient to burst all of them combined. The built-up gun is based on that principle.

The steel in a gun must be of the best quality. In battle the gun will be hit by projectiles; in firing the rifling will be subjected to enormous stress, and the gases formed by the exploding powder have a destructive effect upon the steel.

The United States uses steel made by the "Siemens Open Hearth Process," subjected to the Whitworth process of fluid compression. When the steel is melted it is poured into a strong cylinder and subjected to hydraulic pressure, which squeezes out the gas or air bubbles within the casting and makes the metal much denser and devoid of flaws. Severe tests of the metal are made, and it must show an elastic limit of from 46,000 to 50,000 pounds to the square inch without a permanent change inform. In its test for tensile strength it must stretch at least fifteen per cent before giving way under a stress of from 86,000 to 93,000 pounds to the square inch. The "tube" is cast solid, then bored and a heavy steel shaft (mandrel) passed through on which the tube is subjected to hydraulic pressure or hammer forging to enlarge and elongate it. It is then roughly finished, tempered in oil and sent to the gun factory at Washington. Upon arriving at the shop the tube is put into an enormous lathe and turned to exactly the required diameter, then placed upright in a pit adjoining a furnace wherein the jacket is being heated. The jacket has been carefully bored out and its inner diameter is slightly smaller than the outer diameter of the tube.

It is placed within a chamber, where it is heated by air blown through a white hot furnace burning crude oil. It is subjected to this for twenty-nine hours, until the temperature is raised to about 600 degrees Fahrenheit. It is carefully measured to see that it is expanded enough to go over the tube, seized by a crane, carried to the pit where the tube is and lowered over it at about the rate of a foot a minute until it clasps the rear part of the tube and extends back of it far enough to form the screw box where the breech mechanism is contained. When in the desired position the interior of the gun is cooled by streams of water, When thoroughly cool it is placed in the lathe, the other part carefully turned to a new diameter and the other hoops shrunk on. Each process is expensive and requires the greatest care.

Breech Mechanism

The breech of the gun is closed by a steel plug, threaded and screwed in. In the innerpart of the jacket that projects over the rear of the tube (screwbox), is cut a heavy screw thread. It is then divided into 12 parts and alternate divisions cut away, so that half the screw-box is made up of threaded surface and half of channels where the thread has been cut away. The breech-plug is cut in the same manner, and when in position can be pushed directly into the gun, the threaded portion of the breech-plug fitting the channel in the jacket, and the threaded portion of the jacket fitting the corresponding channel in the breech-plug.

The breech-plug is then given a slight turn and the threaded portion of the plug moves into the corresponding threaded portion of the screw-box, and the breech is securely closed.

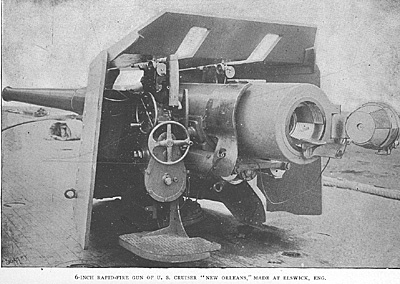

In the cut of the 6-inch rapid-fire gun the breech is open, the screw-box and the threaded portion of the

plug are each shown, but in this case every other sixth part of the

circumference has been cut away, instead of every other twelfth as

in the 13-inch gun.

In the cut of the 6-inch rapid-fire gun the breech is open, the screw-box and the threaded portion of the

plug are each shown, but in this case every other sixth part of the

circumference has been cut away, instead of every other twelfth as

in the 13-inch gun.

6-inch rapid-fire gun of the US Cruiser New Orleans.

By means of a crank-like handle turning bevel gearing, the breech-plug is turned one-sixth or one-twelfth as required, the threads no longer interlock and the plug is moved directly back until it rests on the tray, the whole then swinging to one side, exposing the powder chamber and giving a chance to load the gun. Compare the cuts of the 13-inch and 6-inch guns.

Recoil

The gun moves backward with the same energy the projectile moves forward and if not controlled this force would tear the ship to pieces or drive the gun through the deck.

The cannon of the 4th of July occasions with which the boys are familiar have projections called trunnions on which the guns rest, but no trunnion ever forged could withstand the recoil from a large cannon and even if the trunnions held, it would only be to tear the deck out of the ship. The recoil of a 16-inch gun is more than 64,000 tons, equivalent to lifting 64 loads of hay as high as the Eiffel Tower and yet this enormous force is controlled without allowing the gun to move more than three times the diameter of its bore.

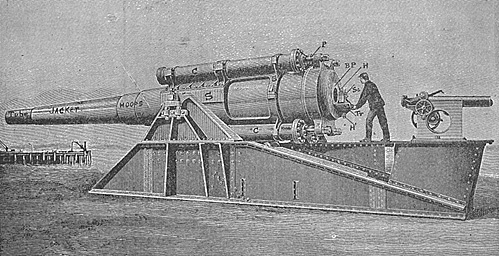

THIRTEEN INCH GUN AT PROVING GROUNDS: S, sleeve; C, cylinder; P, piston; B P, breech plug; H H1, hinges of the tray; Tr, tray; Sc, screw turning Weight, 60.5 tons; Range, 12 miles; Projectile weighs 1100 lbs., and penetrates 22 inches of steel at the distance of one mile. It costs nearly $700 each time the gun is fired.

This is done by means of pistons working in "recoil cylinders" (see cut 13-inch gun). The thirteen-inch has four recoil cylinders fastened to the sleeve, with piston-rods fastened to the rear of the gun. The piston head is attached to the piston-rod and is in the front part of the cylinder when the gun is fired. The recoil cylinders are stationary. When the gun is fired it slides back in the sleeve and draws the piston-rod and head back through the cylinder. The cylinders are filled with water for the heavy guns and a mixture of water and glycerine for the lighter ones.

Grooves are cut in the inner surface of the recoil cylinder and as the piston-licad starts back the water passes the grooves, but in the back part of the cylinder the grooves grow shallower until they disappear, the resistance to the piston-head becoming greater and greater until the gun is brought to a stop with a recoil of only 39 inches. The water in front of the pistonhead escapes through a valve and the hydraulic engine forces water into the cylinder in the rear of the pistonhead which drives it to the front of the recoil cylinder and returns the gun to its former position " in battery."

The total length of the gun is 40 feet; weight, 6o 1/2 tons; the greatest diameter of the gun body, 49 inches; the length of the rifled bore, 30.87 feet, rifling 52 grooves .05 of an inch deep. The projectile for the gun will weigh 1,100 pounds, is made of forged steel; its length about three times its diameter, fired by a charge of 550 pounds of brown powder. This will give a pressure in the powder chamber of 15 tons to the square inch, move the projectile with a velocity of 2,100 foot-seconds, give a muzzle energy of 33,627 foot-tong and penetrate 26 2/3 inches of steel at the muzzle. This gun fires a round in three minutes; the new one will have twice that speed.

The largest gun made in the United States is the 16-inch rifle, which when mounted will constitute a part of the harbor defense of New York City. This is one of the largest and most powerful cannon in the world. The gun when complete will weigh about 140 tons. Its extreme length will be nearly 50 feet, the shell will weigh 2,370 pounds; 1,060 pounds of brown powder will give a projectile a velocity at the muzzle of 2,000 feet a second and an energy of 64,084 foot-tons. Elevated at an angle of 45 degrees, the extreme range of the gun should be 13.6 miles. It will be used only for harbor defense. The friends of the gun claim that no ship on earth can stand the terrible crushing effect of one of its projectiles at close range, and the opponents of the gun say that it is extremely unlikely that a ship in motion could be hit by it.

Twelve-inch Mortars

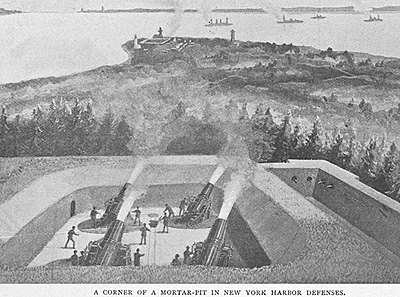

Modern mortars differ only from breech-loading rifles in length. They pass through the same processes of construction, load at the breech and are rifled. They fire explosive shells at a high angle. The shell is expected to describe a huge curve and descend upon the practically unprotected deck of the attacking ship. The thick armor of a ship is carried on the sides to withstand direct fire; it is possible to give but little protection against vertical or "plunging" fire.

The 12-inch mortars defending the harbor of New York

are placed in pits beneath the surface of the ground. Their location

is unknown to the general public, and there is nothing visible at a

distance to indicate their presence. The field defended is laid off

into a series of imaginary squares, and the gunner in the pit trains

the mortar to bear upon any particular square as directed. It is not

necessary that the gunner see the enemy; his movements can be

directed from a distance by telephone. The mortar throws a shell

12 inches in diameter, weighing 1,000 pounds and charged with

100 pounds of explosive. They fire at an angle of 35 degrees to 65

degrees and have an effective range of five or six miles. This half

ton of steel falling from the clouds would easily penetrate the

protective deck of any ship afloat, and even if it didn't explode

in the magazine or machinery compartments, would pass on

through the bottom of the ship.

The 12-inch mortars defending the harbor of New York

are placed in pits beneath the surface of the ground. Their location

is unknown to the general public, and there is nothing visible at a

distance to indicate their presence. The field defended is laid off

into a series of imaginary squares, and the gunner in the pit trains

the mortar to bear upon any particular square as directed. It is not

necessary that the gunner see the enemy; his movements can be

directed from a distance by telephone. The mortar throws a shell

12 inches in diameter, weighing 1,000 pounds and charged with

100 pounds of explosive. They fire at an angle of 35 degrees to 65

degrees and have an effective range of five or six miles. This half

ton of steel falling from the clouds would easily penetrate the

protective deck of any ship afloat, and even if it didn't explode

in the magazine or machinery compartments, would pass on

through the bottom of the ship.

Disappearing Gun Carriages

Heavy guns used for harbor defense are now mounted on disappearing gun carriages. The Buffington-Crosier carriage is probably as good as any, if not the best in the world. The gun is held on four long arms moved by hydraulic or pneumatic machinery. It is loaded beneath the level of the parapet over which it is raised, remains but an instant to be fired and then disappears from sight. Disappearing gun carriages, mines and heavy breech- loading mortars have increased materially the resources of the defense.

Extreme Range

Several years ago a German 9.45-inch Krupp gun with an elevation of 45 degrees attained a range of 12.42 miles. It is estimated that the projectile rose 4.6 miles above a straight line drawn from the firing point to the target; or, in other words, the gun might be fired over any range of mountains in America and hit the target on the other side.

The celebrated "Queen's Jubilee" shot, fired in England, 1888, was made with a wire-wound 9.2-inch gun; the 380 pound projectile was given a muzzle velocity of 2,360 feet per second, and the gun with an elevation of 45 degrees had a range of 12.4 miles. Guns on shipboard cannot be given an extreme elevation. The size of the turret ports will not allow it and the gun in its recoil would strike the deck. Guns in a turret can only be given an elevation of about 17 degrees and have an effective range of perhaps six miles. The extreme range on land is believed to be 7.4 miles for the 6-inch gun; 9 miles for the 8-inch gun; 11 miles for the 10-inch gun; 11 miles for the 12-inch gun; 13.5 miles for the 16-inch gun.

Rapid-fire Guns

In the old style gun the crew must get out of the way of the recoil, the gun must be sponged after each shot to put out any lingering sparks of fire before placing the powder charge, the breech mechanism was clumsy and slow, and after all these operations had been performed the gun must be aimed. Now, ammunition for rapid-fire guns is put up in metallic cases like revolver cartridge; the sponge is not required, the barrel of the gun alone recoils, the sights have been removed from the barrel and placed on the carriage and the gunncr simply keeps his sights on the target, pays no attention to the loading of the gun, and squeezes an electric bulb when the gun is ready to be fired. The great weight of breech mechanism, powder and projectile, precludes making rapid-firers of the extremely heavy guns.

The United States is behind other nations in this respect. On the Chilian cruiser " Blanco Encalada " four rounds were fired in 62 seconds from an 8-inch gun and the ammunition taken from the magazine below the protective deck.

In the English navy a crew at drill fired an Elswick 8-inch gun three rounds in 28 seconds. On board the " Royal Sovereign " a 13.5-inch gun was fired seven rounds in 12 minutes, making six hits on a target at a range of 1,600 to 2,200 yards, while the ship was steaming at eight-knot speed. A similar gun on the " Empress of India " fired four rounds in six minutes. The following table shows what the best guns in the United States navy can do. One or more varieties of some of the guns are made and we have selected the best. The table is compiled from the 1898 edition of Radford's "Naval Gunnery."

| Diameter of Bore | Rounds per minute | Muzzle Velocity | Muzzle Energy | Weight of Shell | Weight of powder | Penetration of steel (inches) |

|---|---|---|---|---|---|---|

| 4-inch gun | 15 | 2,ooo foot-sec. | 915 foot- tons | 33 lbs | 14 llbs. | 7.18 |

| 5-inch gun | 12 | 2,250 foot sec. | 1,754 foot-tons. | 50 lbs. | 28 lbs. | 9 |

| 6-inch gun | 6 | 2150 foot-sec. | 3,204 foot-tons | 100 lbs | 47 lbs. | 11.38 |

| 8-inch gun | 1 | 2150 foot-sec. | 8011 foot-tons. | 250 lbs | 115 lbs | 16.1 |

| 10-inch gun | 1 in 2 min. | 2, 100 foot-sec. | 15,285 foot-tons. | 500 llbs. | 240 lbs. | 20.1 |

| 12-inch gun | 1 in 2.8 min. | 2100 foot-sec. | 25,985 foot-tons | 850lbs. | 425 lbs. | 24.16 | 13-inch gun | 1 in 3 min. | 2,100 foot-sec. | 33,627 foot-tons | 1100 lbs | 550 lbs. | 26.66 |

Secondary Battery

Secondary Battery

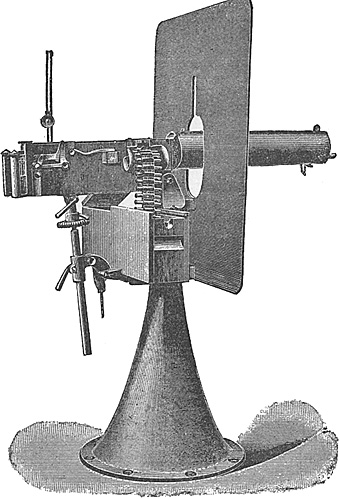

Smaller rapid-fire guns make up the secondary battery. Of these the Maxim, the Driggs-Schroeder and the Hotchkiss are the ones used in the United States.

MAXIM AUTOMATIC NAVAL GUN

Caliber, 0.303-inch; 700 shots per minute can be fired; 500 rounds of ammunition weigh but 44 pounds. This cut shows the belt carrying the cartridges and the tip of the muzzle of the gun surrounded by the "water jacket."

When these 6-pound guns were tested prior to purchase by the Government, the Hotchkiss fired 28 rounds in one minute, 83 rounds in three minutes; the Maxim, 20 rounds in one minute and 65 rounds in three minutes; the Driggs-Schroeder, 34 rounds in one minute and 83 rounds in three minutes. The honors are supposed to be about even between the Hotchkiss and the Driggs-Schroeder. The latter gun is made by the celebrated firm of Cramp Brothers of Philadelphia. The accuracy of the guns is remarkable. Ten rounds were fired at a target 26 feet by 40 feet, at a distance of a mile, all hitting the target, and the most of them pretty close to the center of impact.

Machine Guns

These guns have a caliber and range about equal to that of a modern rifle. The Gatling*, so called from its inventor, Dr. Richard Gatling of the United States, consists of ten barrels (sometimes five), made to turn something like the cylinder of a revolver, each barrel being fired as it comes opposite a given point. The gun is operated by turning a crank, has a range up to 1,000 yards or more, and in the hands of a cool and competent operator is one of the most deadly weapons of modern warfare.

In a test before a naval board 63,000 cartridges were fired without stopping to wipe out the barrels, and at the end of the test the gun was in good condition. Having ten barrels and firing one at a time the Gatling does not heat as do the single barrel guns. Its bore is 30/100 of an inch, bullet weighs 220 grains, has a muzzle velocity of 2,000 feet, and can penetrate 48 inches of pine. A Gatling of .236 caliber using a smokeless cartridge has lately been perfected.

The Colt automatic is a new machine gun recently become familiar to us. It has a thick barrel and does not heat as rapidly from firing and so has no water-jacket. All that is necessary is to keep the finger pressed on the trigger and the gun aimed, and it continues to fire at the rate of 400 shots per minute until all the cartridges are exhausted. The cartridges are carried in a belt and fed into the gun by the recoil, each recoil of the barrel ejecting a shell and jerking a cartridge into place. The bullet weighs 112 grains of .236 caliber, moves with a muzzle velocity of 2,500 feet a second, and will penetrate 60 inches of pine boards. The gun alone weighs 40 pounds; with all its mountings complete, 94 pounds.

The cut herewith gives an excellent representation of the Maxim automatic gun. It is operated the same as the Colt, simply by pressing the trigger. In this case we see the barrel enveloped by a water-jacket to keep cool the parts heated by the friction of firing. Maxim has also made a fully automatic 9-pounder gun that fires 6o shots in a minute.

Projectiles

The projectiles used for breech-loading guns are common armor-firing shell and shrapnel. Common shell is hollow, of cast or drawn steel, containing a bursting charge of powder exploded by a fuse either on impact or at the end of a certain length of time after leaving the gun. In length a shell is usually 3.5 times the caliber. Common shell are used against masonry, earthworks and unarmored sides of vessels, and are effective by reason of the explosion, which sets fire to inflammable material. In common shell a fuse is placed either in the nose or at the base.

An armor-piercing shell made of forged steel with an especially hardened point formerly contained a small bursting charge ignited by heat generated by the penetration of the shell through the armor. Armor-piercing shell are made of forged, oil-tempered steel, treated by special processes, and containing special alloys to allow excessive hardness of point in tempering. Such shells are forged solid, turned to the required dimensions, bored out for the bursting charge, tempered and hardened. The base is closed by screwing into it a heavy steel plug. The point of the armor-piercing shell is covered with a lubricant, and over this is placed a cap of soft steel. The cap dishes the hard face of the armor to its elastic limit, and the projectile then passes through the cap, aided by the lubricant, and attacks the plate when it has left only the local resistance.

Shrapnel shell is made of cast iron or of steel with much thinner walls, and is filled with small leaden balls packed in sulphur, with a small bursting charge of powder. Shrapnel is used against boats and exposed bodies of men. It is intended to explode before reaching the target, and the bursting charge placed in the base of the shell scatters the balls and drives them forward. The sulphur merely holds the balls in place. The compression band is a strip of soft copper fitted around the projectile near its base. The explosion of the charge forces the projectile past the compression slope, the copper is squeezed into the rifling grooves, prevents the escape of the "as and gives the whirling motion to the projectile, probably about 72 revolutions a second.

Smokeless Powder

Black powder when exploded leaves 50% of solid residue, which appears in the form of smoke. A smokeless powder is one that on explosion generates nothing but gaseous matter. The volume of gas evolved from the same weight is much greater in smokeless powder than in black or brown powder, and the force exerted on the projectile is greater. Smokeless powder is usually made from gun cotton, nitro-glycerine, or some of its compounds. In appearance it is hard, lighter than the ordinary powder, pale yellow in color, and usually put up in the form of sticks about of an inch in diameter, having a hole through the center. It also appears in flat strips. The English kind is called "cordite."

Small Arms

The rifle used by the navy is the Lee-Metford, calibre .236; weight of bullet, 112 grains; powder, 33 grains; giving the bullet a muzzle velocity of 2,600 feet a second, and an extreme range of two miles. The Lee has greater penetration and a flatter trajectory than either the Krag or the Springfield at ranges up to 300 yards, and offers a greater rapidity of fire than both when used as a magazine gun.

The bullet has a hard lead core covered with a copper jacket. The Krag-Jorgensen was invented by Col. Krag, chief of ordnance of Norway. The United States pays him a royalty of $1.00 on each gun. This is a magazine gun of .30 calibre; weight of bullet, 220 grains; powder, 40 grains; extreme range, 4,000 yards; muzzle velocity; 2,000 feet. The bullet is a steel shell, filled with lead to give it weight. Beyond 1,000 yards it is a more accurate gun than either the Springfield or the Lee. The Lee and the Krag gun each fire five shots and use smokeless powder. The Springfield is a single shot breach-loading gun, using black powder; calibre, .45; extreme range, 3,500 yards; velocity; 1,300 feet; with a leaden bullet. The wounds made by the small calibre guns at short range are frightful. As the bullet loses its velocity the wound becomes a small, clean puncture.

Next: Chapter 12: The US Army and Its Leaders

Back to The Passing of Spain Table of Contents

Back to Spanish-American War Book List

Back to ME-Books Master Library Desk

Back to MagWeb Master Magazine List

© Copyright 2005 by Coalition Web, Inc.

This article appears in ME-Books (MagWeb.com Military E-Books) on the Internet World Wide Web.

Articles from military history and related magazines are available at http://www.magweb.com