Subplan for Implementing AWPS Has Not Been Developed

AWPS is the Army's second solution for determining workload-based institutional requirements, identifying opportunities to achieve depot efficiencies, and linking workload, personnel, and dollars. AWPS consists of three modules-performance measurement control, workload forecasting, and workforce forecasting-to determine workload-based personnel requirements at the depots, arsenals, and ammunition plants. The performance measurement control module compares actual to planned cost and schedule performance, thereby allowing users to identify problem areas.

This module can identify the work centers contributing to the most significant cost and schedule variances. The workload forecasting module stores project data, labor expenditures, performance data, and scheduling information by work center. This module allows managers to compare workload levels to available direct labor and analyze changes in forecasted workload. This comparison can reveal mismatches or overloads before firm commitments are made to customers.

Finally, the workforce forecasting module contains information on employee skills and leave and attrition rates. This information provides shop and depot managers with an accurate picture of the overall number of employees and the number that are available in each work center. Analyzing the workforce by skill groups allows depot commanders to plan for the amount of work that can be handled and to consider overtime, contracting, or reassigning workers among different work centers.

The Army has been developing AWPS since February 1996. The established goals for AWPS are

- (1) having all three modules operational at all five depots by January 1998;

[7]

(2) operating a supplementary module (i.e., resource schedule and control) for supporting personnel assignments to projects by fiscal year 2000; and

(3) having all modules on line and operational at depots, arsenals, and ammunition facilities by fiscal year 2000.

However, as of December 1997, the Office of the Assistant Secretary of the Army for Manpower and Reserve Affairs had not written the subplan for implementing AWPS or identified the specific steps or milestones needed to achieve the goals. Instead, the Army has set short-term, interim steps as AWPS progresses.

For example, in August 1997, the Army established specific steps for correcting data errors between August 1997 and January 1998. Without a detailed implementation schedule, however, the Army lacks the tools it needs to ensure that it can meet the milestones in the material weakness plan.

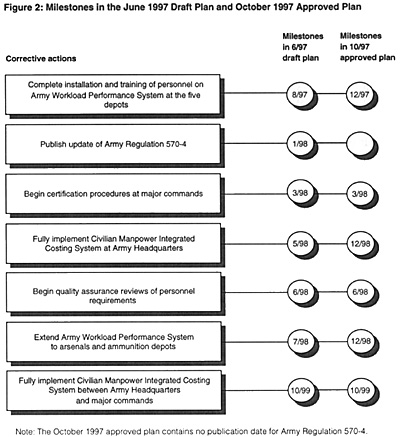

Figure 2: Milestones in the June 1997 Draft Plan and October 1997 Approved Plan

Figure 2: Milestones in the June 1997 Draft Plan and October 1997 Approved Plan

For example, the Army's milestone for implementing AWPS at arsenals and ammunition facilities has already changed from July to December 1998. Figure 2 shows the difference in milestones between the June 1997 draft plan and the October 1997 approved plan.

Implementation of AWPS Has Been More Difficult Than Estimated

Implementation of AWPS at Corpus Christi Army Depot and other locations

has been more difficult than the Army originally estimated. For example, in

response to our February 1997 report, DOD reported that AWPS had been

successfully tested at Corpus Christi Army Depot. Also, the Army expected the

system to be operational at all five depots by March 1997. However,

according to Industrial Operations Command officials, [8]

the Army must still test and validate two of the three modules at Corpus Christi and

correct data errors from feeder systems. [9]

Our review showed that, even though AWPS equipment and software had been

installed at all five depots, none of the three modules is being fully used at any location,

including Corpus Christi.

Army Materiel Command officials cited problems that could affect the Army's ability

to implement AWPS at the depots by December 1997. First, the performance measurement

control module has been undergoing testing and validation since March 1997 and was

planned to be fully operational by December 1997, assuming that the data errors would be

corrected.

As of August 1997, the Corpus Christi Army Depot was correcting data errors and

therefore was not using this module to manage any depot work, not even work at the

shop floor level as the Army had originally claimed. The other two modules are planned

to be operational by February 1998, assuming that the data errors are corrected. An

unresolved problem in the workload forecasting module is how to program work that will

be started in one fiscal year and completed during the following fiscal year. The amount

of repair work assumed affects management decisions on planning and scheduling the

work and the workforce needed.

Second, the Army states in its material weakness plan that AWPS training at the five

depots was to be completed by December 1997. However, as of November 1997, AWPS

users were not fully trained, and some training requirements were not yet defined. Army

officials stated that training on the performance measurement control module has been

completed at the five depots.

However, Corpus Christi Army Depot officials stated in August 1997 that 257 staff

members at the depot have been trained. The depot employs approximately 1,500

personnel. Although not all 1,500 personnel need further training, depot and Industrial

Operations Command officials agreed that additional training is required to teach shop

floor supervisors and depot managers how to interpret AWPs data and how to use it to

identify work areas needing improvement. Command officials stated that training for the

workforce forecasting module was to be completed by December 1997, but training

requirements for the workload forecasting module have not yet been defined.

Last, Industrial Operations Command officials told us that AWPS is still an evolving

concept and that corporate-level system requirements are not yet defined. For example, no

final decision has been made concerning whether this Command and the Army Materiel

Command will install the Decision Support System, which would enable commands to

examine data from subordinate units and help identify processes that could be re-

engineered to improve performance. In December 1997, Army officials decided to add a

material module to monitor ordering and delivery of repair parts.

According to Army officials, the Army could realize benefits once AWPS is

operational and system users are trained. In July 1997, the Assistant Secretary of the

Army for Manpower and Reserve Affairs stated that all depots and arsenals using AWPS

will be able to match workload requirements and personnel projections. Thus, any

personnel reductions will be based on the knowledge of work that will not be performed.

AWPS could also be used for setting performance goals, such as reducing repair costs

and cycle times, but Army officials stated that they have no intentions of using AWPS

for this purpose.

The Civilian Manpower Integrated Costing System will be the Army's distributed,

integrated database for costing institutional personnel requirements and linking workload

and workforce to the budget. Army officials expect this system to provide funding

information for various workload and workforce levels that the 12-step method and AWPS

project. However, the subplan detailing the specific steps and milestones for

implementing the system has not been developed.

Without the subplan, the Army has no mechanism to measure its progress; therefore,

managers will not know whether intervention is necessary to meet milestones. The system

is essential for the Army to effectively prioritize work to be funded and clearly identify

work remaining unfunded.

The material weakness plan includes an October 1999 milestone for implementing the

Civilian Manpower Integrated Costing System at Army headquarters and major

commands and using the system to base institutional budgets on workload analyses. The

plan only includes one interim step, and the milestone for this action has slipped. For

example, the milestone for implementing the system at Army headquarters changed from

May to December 1998.

Also, monitoring progress is essential because offices other than Manpower and

Reserve Affairs are involved. According to Manpower and Reserve Affairs officials, the

Financial Management and Comptroller's office is developing part of the system. The

officials also stated that successful implementation will require compatible

equipment at major commands and training the command's personnel how to

use the system. However, milestones for these events are not identified.

Delays in implementing the material weakness plan's corrective actions could

hamper the Army's efforts to efficiently allocate its institutional resources. The

Army's workload analysis methods (12-step and AWPS) could enhance future

decisions affecting institutional force structure. The 12-step methodology includes

an analysis to structure organizations efficiently and assess whether positions

should be filled by military, civilian, or contractor personnel. Such information could

be useful to managers in deciding how to allocate reductions with the least effect

on accomplishing institutional missions.

The Army programmed reductions of 6,200 institutional positions during fiscal

year 1998 and another 7,000 positions between fiscal year 1999 and 2003. The

Quadrennial Defense Review mandates further reductions of 33,700 civilian

positions and some active Army positions. Delayed implementation may result in

these planned reductions being made without the benefit of workload analysis and

assessments of risks and tradeoffs.

Footnotes

[7] The five depots are: Corpus Christi (TX), Anniston Army Depot (AL), Red River Army

Depot (TX), Letterkenny Army Depot (PA), and Tobyhanna Army Depot (PA).

[8] The Industrial Operations Command is the headquarters command for all Army maintenance depots, arsenals, and ammunition plants. It is a major subordinate command of the Army Materiel Command.

[9] AWPS uses data from three feeder systems: the Standard Depot System, Army Time Attendance and Personnel System, and Headquarters Accumulation System.

Costing System Subplan Has Not Been Developed

Delayed Implementation Could Hamper Downsizing Decisions

Back to Table of Contents Force Structure US Army

Back to GAO List of Issues

Back to MagWeb Magazine List

© Copyright 1998 by US GAO.

This article appears in MagWeb.com (Magazine Web) on the Internet World Wide Web.

Other articles from military history and related magazines are available at http://www.magweb.com