I am a compulsive painter, fiddler, tinkerer, converter, and experimenter. Had my mind been more focused I might have made something of myself. Now it’s too late.

I am a compulsive painter, fiddler, tinkerer, converter, and experimenter. Had my mind been more focused I might have made something of myself. Now it’s too late.

One of the things I have been fiddling with for years, as an ancillary to my war games was an effective method of carrying miniatures. Now I have seen a lot of systems and noble efforts, but all of them fall short. The problem is two-fold. First getting a carrying vehicle that can accommodate the figures, and second, one that will secure them without the use of bits of styrofoam peanuts, layers of felt, or gluing magnets to the bottom of the figure (which doesn’t work all that well in practice either.) Besides, I could never take the latter seriously. I always thought of those electric football games we had when we were kids where you set up the little guys on the sheet-metal field (they all had magnets underneath) and then turned on the set and a small vibrator shook the teams together.

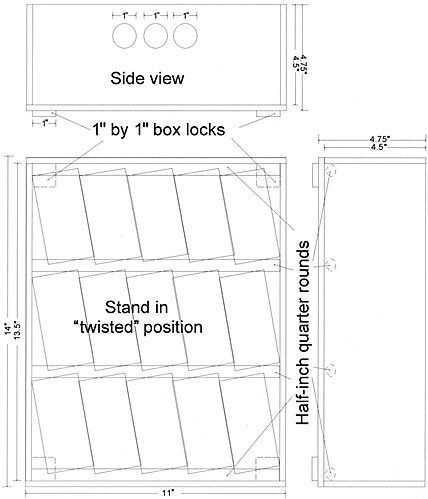

After several failed tries I came up with what I think is a very good system and has served me well in the past. My original idea was for a much larger case, but it proved too unwieldy, and, besides, you can’t make these things too big because... well... we ARE carrying lead after all! The basic idea, and I’ll get into the details in a minute, is an open-topped wooden box made of 1/4” luan plywood. Underneath, and inset from the edge, are four lugs 1” square which “lock” into the base below when you stack them up, and this keeps them from tumbling over. The sides are perforated with three “finger holes” to pick them up with. The key to the whole thing, however, is in the base of the box. Here pieces of half-inch, or three quarter inch quarter round (your choice) are glued and screwed into the base to provide “catch rails” to hold the troops firm in the box. How this is done, the holding of the troops, is quite simple really. It relies on “catching” the edge of the stand and wedging it into the corners formed by the quarter round.

To do this you simply slide in one side of the stand under one of the quarter round rails, and then lay the stand flat. Then simply “twist” the stand slightly as shown in the diagram, and it will wedge the two diagonal corners of the stand into the crannies on the base. The stands can’t slip out because when you wedge another stand behind them they have nowhere to go, and you can make several pieces of small bogus stands with no figures to take up the end space. Once the troops are secured this way you can drive over pretty bumpy roads and even suffer a tip-over, and few, if any of the stands will break loose. I once rode back from a “Historicon” with two of the boxes purposely inverted to see what would happen. It was a pretty severe test and only two stands out of 40 broke free, and in both cases it was because the stands themselves were fairly crummy.

The other benefit to this is that you can stack them up and move them around easier. Now one thing I should mention is that the stands used in the diagram are 2” by 4” in size. I am somewhat of a rogue gamer in that I use very large stands for my troops. I like it, it keeps them from getting broken, bent, or touched too much, and it also looks better. Even 2” by 4” therefore is small for me, and is what I put my light troops on. Regular infantry regiments are on huge 4” by 8” stands with up to 48 figures on them. My point in bringing this up is that while the quarter round is shown positioned for a 4” frontage stand, you can move the spacing around on some scrap wood to get the best dimension for your own troops.

Obviously, with smaller stands you will have less spacing (but you don’t get that many more figures in the box than I do.) After all, the little guys still take up the same space. You may not like the idea of the “twist” to the stand, but believe me it works! The stands wedge in there and don’t slide around at all. I once made a version of this with a drop-front box and I could slide them in like coke cans in a dispenser rack, but that was too cumbersome, took a lot of time, and the box structure was weakened by the door and hinges (and of course it was more expensive to make.)

Another possibility you can try, if you don’t like the use of molding, is the plastic pre-formed “I-Beams” from Plastruct, but that’s a little more expensive and I don’t think they will work as well. My reason for the quarter round was simply that it can be gotten anywhere, and fairly cheaply. One other note, the height of the box is shown at 4.5” to accommodate my pike formations and lance armed cavalry. If you are not working under this need, you can cut the height down, or if you have 15mm, you can make it much lower and get more boxes out of the sheet, though you will have to revise the cutting diagram I have given you.

You may wonder at the odd dimensions of the box. This is for a very simple and very logical purpose. You will probably have noticed that this 11” by 14” is the standard size of a fan-fold computer paper box. Staples and other stores sell cheap carrying dollies or hand-trucks for paper and files (only about $30.00) that look like those luggage dollies all the yuppie crud carry at the airport (you know, the suitcases with wheels which they INSIST can be fit under the seat, but which they cram into the overhead in YOUR space and crush grandma’s cookies to crumbs.... but I’m not bitter...). This box can easily fit into those to be carried around, and you don’t have to lug it by hand. With the locks you can stack them up, tilt them, and tote them that way. If you want to use an open hand-truck the boxes could be somewhat larger — but remember— don’t get it too large or it will be too unwieldy to handle.

I once was quite pleased with myself when I made a version of this in a 3’ by 3’ box which had a hinged lid. The top of the lid had the playing surface for the game at the con, and in the box underneath the six sections (making a 3 by 9 table) I had all the troops and terrain, each in a carrier that could be drawn out for ease of loading and unloading the troops.

Sounds good eh!? Too bad I forgot that the doors in the hotel are only 28 to 30” wide and they had to be up-ended to get in and out of the room, and they were ENORMOUSLY heavy. That design didn’t last long!

Another dead end you might be tempted to run down is to put the draw-handle locks, like they have on old steamer trunks, on the boxes to unitize them. Sounds good but unless you are already a skilled cabinet maker you will have a devil of a time ensuring that each latch and hasp is exactly in the same position on each box so they are interchangeable. If you don’t it will be like that kids game “The Temple of Hanoi” with the three posts and the stepped rings and you’ll be trying to figure out how they all go together (and you’ll never get it right). Remember, for use at a con, or anywhere, time is of the essence and you want to get a quick set-up and break down.

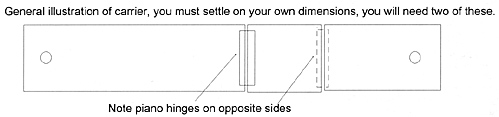

One other reason I made it this size was that the boxes will fit into the carrying dolly with ease and leave a bit of space on each side. This will allow you to make a “carrying camel” for the thing which will allow oversized boxes to be placed on top of the miniatures and save trips back and froth to the room or the car. Bungee cords can then be used to secure the camel to the handle, and strap over the boxes.

One other reason I made it this size was that the boxes will fit into the carrying dolly with ease and leave a bit of space on each side. This will allow you to make a “carrying camel” for the thing which will allow oversized boxes to be placed on top of the miniatures and save trips back and froth to the room or the car. Bungee cords can then be used to secure the camel to the handle, and strap over the boxes.

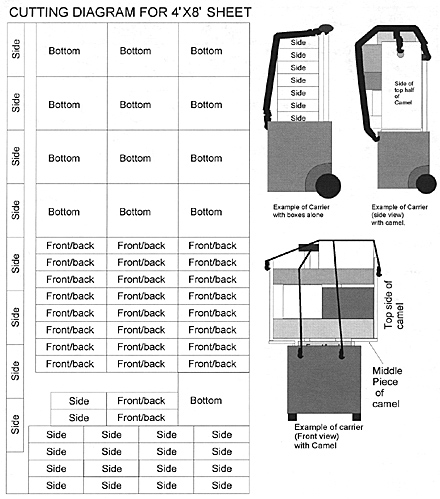

The boxes are made out of 1/4” luan plywood, available in pine or cedar and available at any lumber yard. The cedar is a bit softer but it smells nice, and this might be an asset as an auxiliary air-freshener in a room with a bunch of guys at a convention. It also gives your figures a nice “homey scent” so it might throw off the opposition. One sheet will give you eight boxes and a GENERAL cutting diagram is shown in the illustrations. You will have to measure very carefully!. I don’t recommend mapping the whole thing out and then cutting it up at once. Rather, nibble away at the sheet a few sections at a time. Cut off enough to make one or two boxes, and then they are done, go back and cut some more. This will prevent you ruining a whole sheet should you make a mistake, and better still, allow for minor corrections as you go along.

To cut the sheet the best thing is a good jig or power saw with a fine-toothed metal blade. A table mounted scroll saw is also good for fine finishing, but you will have trouble working a whole 4/8” in doing it. If you want the nice clean cuts of the scroll saw, lop off an 20” wide section at a time. Remember to cut the pieces from the BACK (or rather from the side you want on the inside of the box) because the saw will mar the surface of the side facing you.

To drill the finger holes, you’ll need a power drill with a 1” auger. You can leave these off if you want, but they are real handy, and are definitely worth the extra trouble.

Joining the pieces is pretty easy Sand the edges with a belt sander to take off the burrs from the saw edge and give a good surface to the blue. Glue the box sides, front and back and the base together with hide glue or carpenters glue. I wouldn’t use Elmer's white glue, its not water and moisture resistant enough and will not give a strong bond. Clamp the pieces on all four sides (so you’ll need four to eight clamps with a capacity as large as the box, or better yet four miter clamps). Once the stuff is clamped, drill pilot holes for the screws and attach each piece (sides, front and back) to the base with three #4 5/8” wood screws to make the joint firm. Put four screws, two on each side of each side piece to secure them. Once the screws are in you can take off the clamps and go on to the next box. Let the box dry overnight. You could use bolts or metal reinforces, but that’s a bit clunky and doesn’t look as good. You can dispense with the screws and for most cases the box will be just fine, but it will be weaker than a screw reinforced construction. In all cases, if you aren’t using screws, leave the clamps on until thoroughly dry. They press the glue into the grain and fiber of the wood and make a stronger joint. Wipe off any excess glue with a damp, hot rag.

Once the box is dry, go over the surfaces with an orbital sander (especially the edges and where you have glued). The wood can still give you nasty splinters, and wood reinforced with glue can give you a savage cut. Better safe than sorry. Locate the lugs so they will lock onto the box below them. To do this cut the 1” by 1” sections and glue and screw them into the base using #2 1/2” screws. Do one screw in each until you have the setting right and then glue and set with two screws. Doing this step before painting (if you are going to paint them, I never bother) might cause the boxes not to nest into each other because the paint may take up the space. If you want to paint them, then make the lugs fit even a bit looser.

Once the lugs are in you have to set the quarter round runners. This is the hard part because you have to screw the thing down while it is on the 90 degree corner. A very unstable perch! The best way to handle this is to first take some scrap wood and figure out how far apart your two pieces of quarter round will be. If you were using a 4” stand like me, about 4 1/2 to 4 3/4” would be about right, BUT BE SURE AND EXPERIMENT FIRST! Once you have the distance down, measure this out on the UNDERSIDE OF THE BOX and drill holes with a small sized drill (1/16th or 3/64). Drill three holes on that line.

When you are ready to put them in, and have cut the quarter round, start the screws in the holes till they protrude about 1/16th of an inch into the base. Then glue the corner of the strip and hold up the corner to the edge of the screw. Now drive the screw home while holding the quarter round. The screws should “bight” immediately into the soft pine quarter round. Finish the other two screws. Wipe down thoroughly. Test with a bogus stand to make sure that it works. NEVER LEAVE A STAND in the locks or the like until the glue is thoroughly dry. If you do you may not be able to get the stand out.

THE CAMEL

The Camel is really a very simple item that is just three pieces of luan plywood secured with two lengths of piano hinge. It is very flimsy, weak, and floppy, but exists ONLY to provide a surface against which bungee cords can press and unitize a load. One could me them much sturdier, but they would not then be collapsible and easy to store, and the benefit gained would largely be lost. What they provide is an extension to each side, not to support the boxes, but to enable oversized boxes to be placed on the carrier and secured. Obviously if you aren’t using a “bucket based” type of dolly the camel won’t work. The illustration pretty much says it all as to how the camel is made and used.

The Camel is really a very simple item that is just three pieces of luan plywood secured with two lengths of piano hinge. It is very flimsy, weak, and floppy, but exists ONLY to provide a surface against which bungee cords can press and unitize a load. One could me them much sturdier, but they would not then be collapsible and easy to store, and the benefit gained would largely be lost. What they provide is an extension to each side, not to support the boxes, but to enable oversized boxes to be placed on the carrier and secured. Obviously if you aren’t using a “bucket based” type of dolly the camel won’t work. The illustration pretty much says it all as to how the camel is made and used.

The illustration shows the most economical way of cutting the luan. This will give you 8 boxes large enough for 25mm troops. Considering there are four strips 1/2” wide, that”s two inches off the side to side dimension making the useable surface area about 10.5 by 12.5 inches, which is 131.25 square inches of remaining space. Knock off about 5% of the area because of the “twisting” means about 124 square inches. Given a 25mm figure takes about one square inch of space for infantry and 2 square inch for cavalry, that means enough carriers from one sheet to transport a total of 1000+ infantry or 500+ cavalry.

Back to Table of Contents -- Courier #85

To Courier List of Issues

To MagWeb Master Magazine List

© Copyright 2002 by The Courier Publishing Company.

This article appears in MagWeb (Magazine Web) on the Internet World Wide Web.

Other military history articles and gaming articles are available at http://www.magweb.com