So you want your own Panzer Brigade? You've come far enough in the hobby to want a realistic looking group of armored vehicles to spearhead your next well- planned attack. The best way to get this is to build 'em yourself. The 1/72 and 1/76 model kits available today are highly detailed gems that if built and painted will look great on a game table. The biggest drawback to these things is assembling them; it can be a real pain. The very tiny parts (lots of them) complicate the job. From my experience, I will try to pass along whit I think eases the transformation from piles of plastic to armored might.

The biggest key to success is a liquid styrene glue. The old tube glues just won't cut it here. The liquid is placed exactly where you want it with the tip of a paint brush. A #3 brush works best. Too large of a bursh picks up too much liquid which can melt tiny axels and gun barrels. Tenax 7 seems to me to be the best all round product as it flows beautifully and dries very fast. This fast drying is important when you're putting on sixteen (16) miniscule road weels per side, or dealing with warped hull bottoms from bargain kits.

Does your significant other go to Tupperware parties? What, you may ask, does Tupperware have to do with model tanks? To me it is an intergral part of the assembly of large numbers of tiny war wagons. We need these containers because we're going to build more than one vehicle at a time. A productionline type assembly is the way to go.

A Tupperware container about 56" square and 1 1/2 " high is the ideal storage place for tiny parts that are cut off the sprues; and larger 12" x 12" sizes are good for storage and transportation of finished vehicles. These have covers that snap tight.

If the family cat, kid or even Murphy knocks 'em over while you're engaged in other pursuits (like making money to buy more tanks, for instance) your idlers and sprockets won't be scattered all over the landscape.

Another definite must for this project is an Xacto #1 knife handle and a good supply of # 11 blades. Sharp, pointed blades are required for cutting all those road wheels and hatches off the sprues.

Another place the Xacto # 11 blade comes in handy is when trying to pick up really microscopic parts, like track upper rollers, tow hooks, and vision ports. Tweezers sometimes won't even do the trick on these parts. Just take the tip of the blade and gently poke it into the part. This will usually pick the part up and come off the parts once they are glued where they belong, and leave no marks that can be noticed.

Well, lets get the line moving!

Begin with the worst part; the suspension. Some models of vehicles here are much better than others in this regard. German half tracks are the worst, with many interleaved road wheels that are really small. Panthers and tigers are also a gas, but at least they're larger. God bless these T-34s (only 7 per side).

On a wooden

cutting board, take the sprue containing the wheels and

cut them ALL off. Press down on the knife tip as close as

possible to the wheel so as to leave as little junk as

possible on the wheel (Fig. 1). Refer to the kit

instructions as you do this to get an idea of what goes

where (on most kits you really

don't mix up the different wheels). Keep the finger

opposite your knife hand on the part itself to avoid having it

fly across the room when the cut is made. As you cut,

place them all in your Tupperware container until all the

wheels are cut for as many kits as your doing.

On a wooden

cutting board, take the sprue containing the wheels and

cut them ALL off. Press down on the knife tip as close as

possible to the wheel so as to leave as little junk as

possible on the wheel (Fig. 1). Refer to the kit

instructions as you do this to get an idea of what goes

where (on most kits you really

don't mix up the different wheels). Keep the finger

opposite your knife hand on the part itself to avoid having it

fly across the room when the cut is made. As you cut,

place them all in your Tupperware container until all the

wheels are cut for as many kits as your doing.

Now, chop off all the other suspension parts the plans say you need; leaf spring assemblies, bogie trucks, support arms, and hull sides with axles on them.

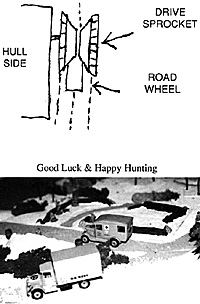

All go into the container; now assemble one hull side with wheels as per plans. Now you'll appreciate that fast drying glue, when you're trying to keep those wheels lined up and straight. Make sure the drive sprocket (the big one with teeth) is lined up with the road wheels or this can make track installation interesting (fig.2).

By the time you put on the last wheel, everything

should be pretty set up, so check for alignment and how

straight it looks. Put this part aside and start another one.

By the time you put on the last wheel, everything

should be pretty set up, so check for alignment and how

straight it looks. Put this part aside and start another one.

By the way, if this production line method makes you nervous, you can always build a single kit all at once for reference, then build the rest of them assembly-line style, when you are familiar with the parts and what goes where.

Once you are done with five (5) or so sets, go back to the first one you did, which should be dry enough by now to glue onto the hull floor. Tack on the hull front and rear plates as per instructions. On half tracks, install front axles and wheels. Remember, keep them lined up nice and straight for best looks on the battlefield.

Quality

A word here about the quality of plastic kits is in order. There are bargain kits around, packaged in plastic bags. The price on these is good, but sometimes they have been lying around for a long time. Parts tend to be broken and warped, or to be made of very brittle plastic (quality control rejects). This can make cutting the parts off the sprues bad news as they sometimes fracture into several pieces. Warped hull sides and floors are easier to deal with when using good liquid glues. Just take extra time to hold things in alignment until the glue sets up. Remember, "You get what you pay for".

Back to the line

Now tackle the upper works. Go back to the cutting board and slice off the hull, tools, hatches, etc. and into the container they go. Put everything on as many at a time as you want. Now, anytime you develop the severe eyestrain that's bound to happen, or you want to eat dinner, or something else interrupts your work, just snap the cover on the old tupperware and put it out of reach somewhere, and accidents will be rare.

Finally, cut out all the turret parts, containerize and assemble as before. Scrape those ugly seam lines off the gun barrels with your trusty # 11. (and lots of luck with those muzzle brakes). That, my friends, is the subject of the next issue's article as the" treads" supplied with most kits have their share of problems to conquer.

If you can't wait for my advice, just remember, don't attempt to put on those tracks until the wheel assemblies have dried for 24 hours.

Back to Table of Contents -- Combat Simulation Vol 2 No. 3

Back to Combat Simulation List of Issues

Back to MagWeb Magazine List

© Copyright 1996 by Mike Vogell and Phoenix Military Simulations.

This article appears in MagWeb (Magazine Web) on the Internet World Wide Web.

Other articles from military history and related magazines are available at http://www.magweb.com