A couple of months ago, Scott asked me if I would like to write a few more articles on ACW terrain making and I agreed to do so. I picked the topic of ACW forts since that would nicely supplement Bruce Kindig's suggested rules from Issue #5 of CHARGE! Since this is a wide topic, it will be divided into a number of separate articles. So for this issue, we will start with brick and masonry forts. The text will describe how I build one casemate for a single-story fort. This can obviously be expanded into a complete fortress, or into one with multiple stories, by making it longer and building more stories atop of the other.

A couple of months ago, Scott asked me if I would like to write a few more articles on ACW terrain making and I agreed to do so. I picked the topic of ACW forts since that would nicely supplement Bruce Kindig's suggested rules from Issue #5 of CHARGE! Since this is a wide topic, it will be divided into a number of separate articles. So for this issue, we will start with brick and masonry forts. The text will describe how I build one casemate for a single-story fort. This can obviously be expanded into a complete fortress, or into one with multiple stories, by making it longer and building more stories atop of the other.

Building materials:

You will need Foamcore, white craft glue (such as Elmer's Glue), a sharp pencil, a ruler (preferably metal), a sharp knife (preferably a scalpel), and a circular cutter and a colour printer with both normal and heavy paper (105-110 lbs.).

Foamcore will be our basic building material. Essentially it is dense foam sandwiched between two layers of card. In my opinion, it is the perfect building material for this project since it is reasonably strong, lightweight, and easy to cut into shape. It can be bought in almost any craft store or at some photo shops. You can also use plywood, but that is harder to cut, although being more stable.

A circular cutter can be bought at any craft store for less then 10 US$. If you do not want to invest that amount, you can also use any object that allows you to draw a circle and cut along that line.

Procedure

Procedure

You should start by measuring the models of the guns that you want to use. It is important that you know how high the bottom and top of the muzzles are above the ground, as this will dictate the size of the firing ports. You will also need the total height of the gun, as well as the length of the carriage and the distance between the point where it would hinge and the support wheels.

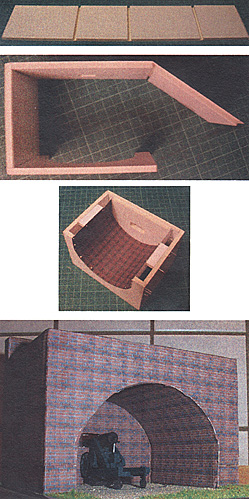

Now the time has come to cut your walls. They should be between 2 to 2 V2 times as high as the gun itself. Cut a strip of Foamcore that is as wide as your walls are high. Each casemate should be 3/4 as wide as the carriage is long, plus twice the thickness of your walls. In this context, thickness is not how thick your Foamcore is, but how thick you would want your walls to look (though it is best to pick a figure that can be divided by the thickness of your Foamcore). If you want to build more than one casemate, multiply the width by the number of casemates. You can now cut two strips of this length from your wall strip (one for the front and one for the rear wall). Mark the width of each individual casemate (if you are doing more than one) on the Foamcore. These segments will later tell you where each casemate will be.

Front wall: In the horizontal middle of each front wall segment, cut a hole that starts a little less from the floor than the muzzle's bottom and is a little higher than the muzzle. The hole should be about 1 1/5 times as wide.

Rear wall: In the horizontal middle of each rear wall segment, you will cut the arch for the casemate. First mark the thickness of your walls from each side of the segment at the bottom (the space between these marks will be equal to the width of the casemate). From those spots, you will have to mark a line straight up for about as high as the gun itself. You will now draw a circle that touches the ends of both lines. It is good if your circle is actually wider than the width of your casemate (which means that the centre point of your circle will be lower than an imaginative line drawn between the ends of both lines) as this will give you a mild arch that is more pleasing to the eye. Cut this out, trying not to damage the piece that you cut out. Make another hole with the same size as your firing port in the horizontal middle of this piece. Make sure that it is exactly as far above the ground as your firing port. Now glue this piece onto your front wall, making sure that the firing ports overlap. It will take some time for this to settle (usually about an hour) during which time you should keep everything in place by fixing it with needles. These will be removed once dried.

Now it is time to cut the walls for the end of each segment. These will not need any holes in them, so you simply cut pieces that are as high as your walls and have the desired depth of the batteries. This depth should be 1 1/2 times as much as your carriage is long. Make it a little bit longer if this is the ground floor for a multi-story structure. (Instead of cutting the front, rear and side walls, you can also cut one long strip that is as long as all walls combined. In that case, you will need to cut out a vertical strip at the right hand side of each wall, making sure that you only cut the inside card layer and the foam. You can then fold the walls. This will in the end produce nicer edges but is a little more complicated).

Assembly:

Now you will have to glue all of the walls together. Put some white glue on the ends of the side walls (or into the fold if you go for the folding technique) and glue the front and rear walls to this. Again fix everything with needles.

Now you will have to take care of the inside walls of the casemate. These were usually constructed from bricks, which actually makes this fairly easy and fast to model. You will need to print a brick structure onto heavy paper. You can find this online on sites for homemade dollhouses or computer graphics (mostly first person shooter games). I have prepared a file that can be downloaded from the Yahoo Groups JR3 website (http://games.groups.yahoo.com/group/jriii/files/). Import this into a word file, resize it according to your scale, paste and copy it to fill the whole page, and then print it out.

Cut the white borders away and bend the paper a little. Put a small amount of white glue on top of the edges of the arch's cut-out and the inside of the arch, and then glue the brick print to it. Make sure that the printed side faces the inside of the casemate, that the brick lines run horizontally, that the side of the printout touches the inside of the front wall, and that the paper is pulled tight. You will again have to fix this with pins.

Once dried, you will have measure the distance between the front and the rear wall, as well as between the side walls in each corner. Cut a piece of Foamcore that fits these values (this will be the roof) and place it inside the hole on the top of your battery. Again fix with pins. You will now have to do the wall for the battlement (if this is your only or top floor). These should be about as high as the underside of the muzzles of the guns you want to place on the parapet, or, if you do not want any guns up there, about shoulder height for your minis. Glue as many layers behind one another until you match the thickness of your walls. Glue this on top of the roof at the front.

Once all this is dried, it comes to giving it all the look of a finished structure. There are two ways to achieve this. There were forts there were almost exclusively build from bricks. Simply print the brick texture out on normal paper and glue it to all walls like wallpaper, again making sure that all lines run horizontally.

The other type of fort had its main walls built from massive stone blocks. To model those, you could either draw stone blocks onto the outside walls and roof using a blunt pencil and enough pressure to make an impression (obviously do this before assembly) or cut rectangular shapes out of the heavy paper and glue them onto the walls to represent the stone blocks. No matter which route you decide to go, you can then paint it all in a desired colour and dry brush it for the desired effect. To create a complete fort, you will need corners. Those can be simply constructed by cutting all walls to the same length.

Back to Table of Contents -- Charge! # 6

Back to Charge! List of Issues

Back to MagWeb Master Magazine List

© Copyright 2005 by Scott Mingus.

This article appears in MagWeb.com (Magazine Web) on the Internet World Wide Web.

Other articles from military history and related magazines are available at http://www.magweb.com